PVC Plastisols are produced with a wide range of features and in various colours. Plastisols are very resistant against climatic conditions and also have good chemical resistance properties. The expansion of finished products is also possible.

The basic characteristics of plastisols are viscosity and hardness of Shore A. The viscosity behaviour influences the processing capacity of plastisols, Shore A hardness is a typical property of finished products.

PVC plastisols are processed using various technologies, for example:

- squeegee coating

- dipping

- pouring

- rotary pouring

- rotary imprint

- silk screen imprint

- spraying etc.

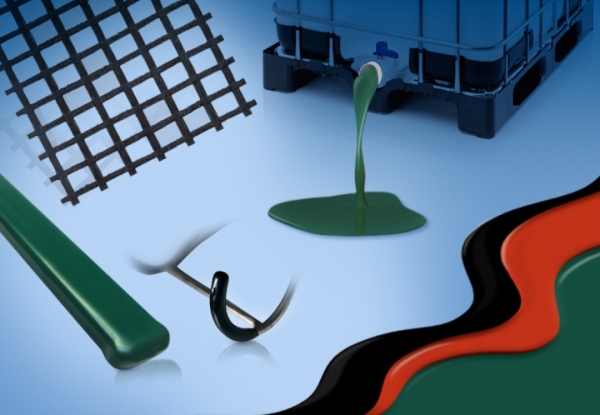

PVC plastisols are used for

- manufacturing anti-corrosive, chemical-resistant, protective and decorative plastic covers for metal objects

- manufacturing caps, handles, grips and shaped technical components

- treating woven, non-woven and knitted textiles (geotextile grates, water insulation wraps etc.)

- layering textile or paper (wallpaper)

- manufacturing hollow objects of various shapes and sizes for technical and decorative purposes, such as balls, toys, figures, advertising material etc.