Viplanyl

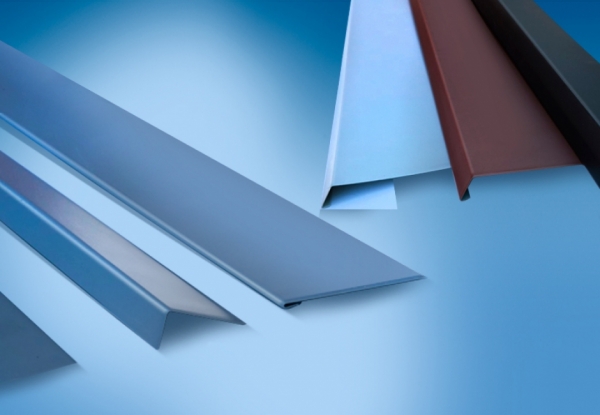

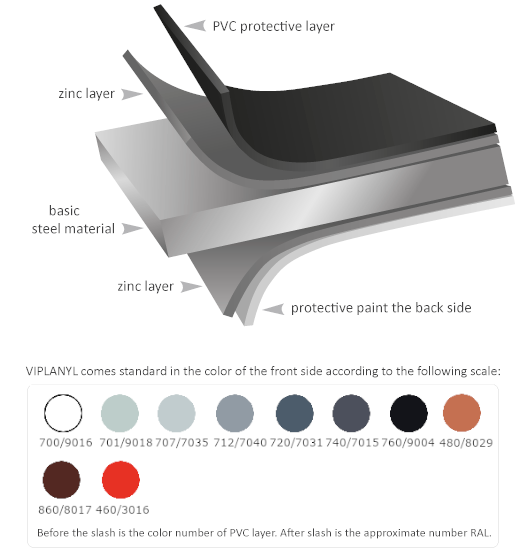

VIPLANYL® plastic-coated sheet is used as a terminal or anchoring sheet component for applying PVC water insulation wrap. VIPLANYL® is a composite material formed from a metal basic material and from an organic coating which merges the excellent characteristics of both listed materials

You can find more information in the technical data sheet.

Processing the plastic-coated VIPLANYL® is similar to the processing of sheet metals without a PVC layer with the difference that the sheet metals cannot be connected by soldering or welding. The PVC layer does not require any additional surface treatment using a surface coating. The sheet metals are not designed for contact with drinking water and other eatables thinks.

Stenyl

Stenyl sheet metals are zinc coated, with the surface protected by a layer of softened PVC. Standard thickness of the PVC layer of 4-5 mm. Stenyl sheets are designed for protection against abrasion during transport and manipulation especially in the automotive industry.

On request, we will make a preparation of semi-finished products from this sheet metal for further processing (cutting to the required dimensions, bending, drilling, etc.).

You can find more information in the technical data sheet

Others

As a protection against abrasion during transport and manipulation in the automotive industry, we also offer other types of zinc-coated sheet metal protected by a layer of softened PVC:

- Plastic-coated sheet metal 2000 x 1000 x 0.55 mm with a layer of PVC of 1000 – 1200 microns.

- Plastic-coated sheet metal 2000 x 1000 x 1 mm with a layer of PVC of 1000 – 1200 microns.

On request, we will make a preparation of semi-finished products from this sheet metal for further processing (cutting to the required dimensions, bending, drilling, etc.).